In the era of digital business, a company is only as good as its supply chain. On the journey from raw materials to finished product, the ability to integrate external information flows from partners and suppliers with internal business systems such as enterprise resource planning (ERP) and inventory management can be transformative. Companies that have this ability can build a seamless digital foundation to support an intelligent business ecosystem capable of delivering market-leading products rapidly and economically.

Small changes in any part of the supply chain can lead to big changes in outcome, with a significant impact on a company’s ability to produce and compete in industries where disruption is the norm. Organizations should constantly search for improvements to the workings of Market Pulse WHITE PAPER Connecting, integrating data seen as crucial, but IT faces data quality and skills challenges STRATEGIC MARKETING SERVICES Sponsored content IDG Communications, Inc. their supply chain so as to achieve lean operations; increase responsiveness to supply chain partners; and address customer desires for product quality, variety, and timeliness.

A new IDG Research MarketPulse survey provides insight into how companies are integrating their supply chain systems with their partners and suppliers, the benefits of integration, and the pain points companies are encountering. The survey respondents are at companies with 500 to 100,000 or more employees, with job titles ranging from manager to executive vice president to CIO. All respondents are familiar with supply chain operations.

MarketPulse survey results

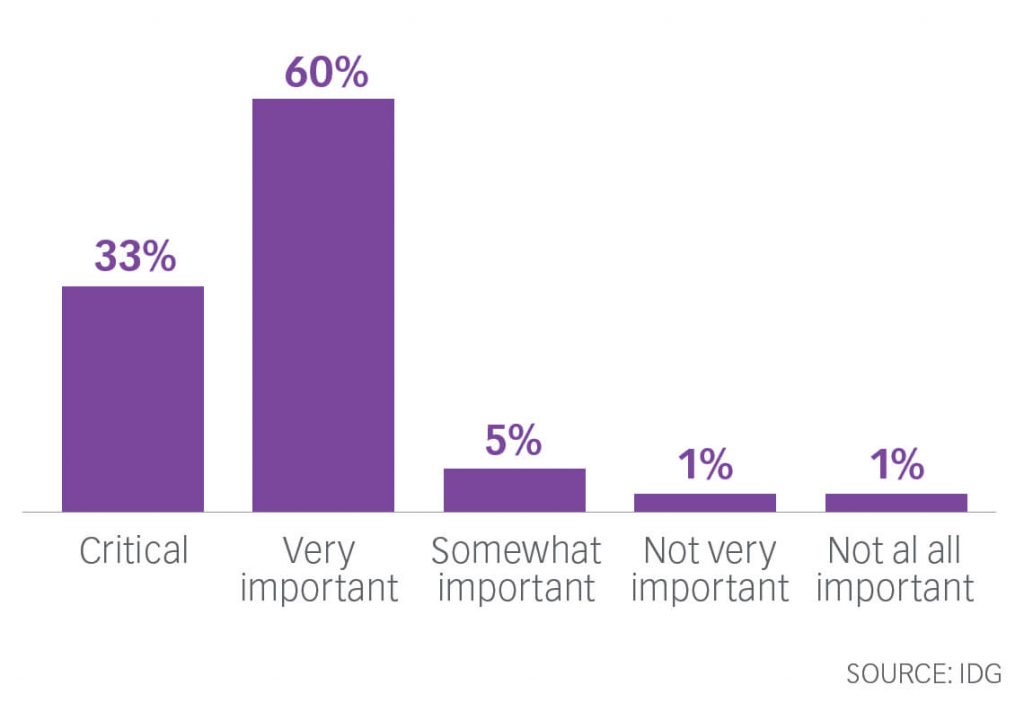

Supply chain integration is a critical success factor. The survey respondents were nearly unanimous (93%) in saying that it is important to connect and integrate transaction data from supply chain partners (33% said it’s critical, 60% very important) (See Fig. 1).

In practice, companies must connect and integrate transaction data from their supply chain partners with their internal enterprise systems, including transport management, warehouse management, inventory management, and more. When these systems are fed timely, accurate, and complete data from external partners providing raw materials, services, or logistics, a company gains end-to-end visibility into the entire procure-to-pay continuum. With that awareness, an organization is well positioned to optimize processes, with the goals of executing faster, increasing quality, and cutting costs. The result is a significant competitive edge.

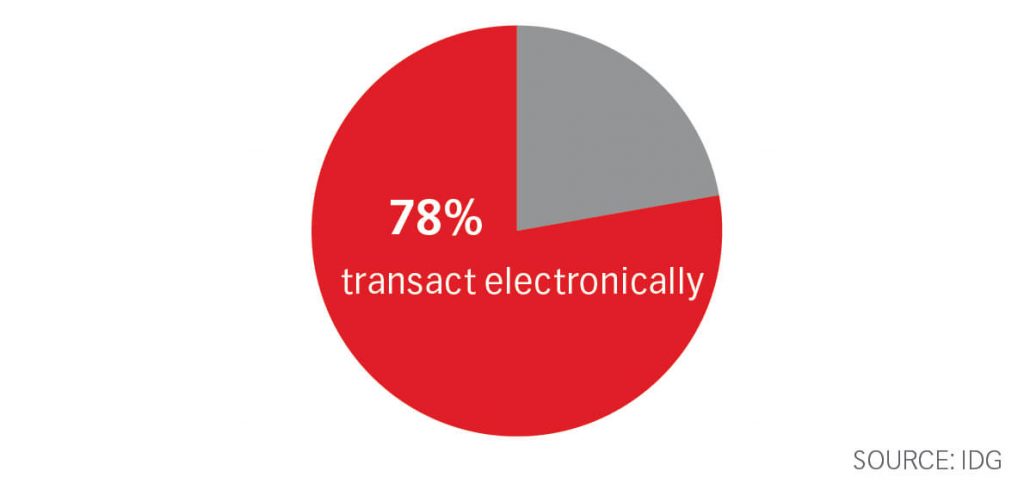

Given the tremendous importance of supply chain integration, it’s encouraging that electronic supply chain transactions are widespread: 78% of the survey respondents transact electronically with more than half of their external partners. Because digitized transactions take place much faster and more cost-effectively than outmoded paperbased transactions, companies that have not yet digitized their supply chain are operating at a distinct disadvantage. (See Fig. 2)

However, the move to electronic transactions across a connected supply chain does not happen automatically. It requires specific expertise as well as planning and coordination with supply chain partners.

Supply chain integration challenges: staffing, data quality

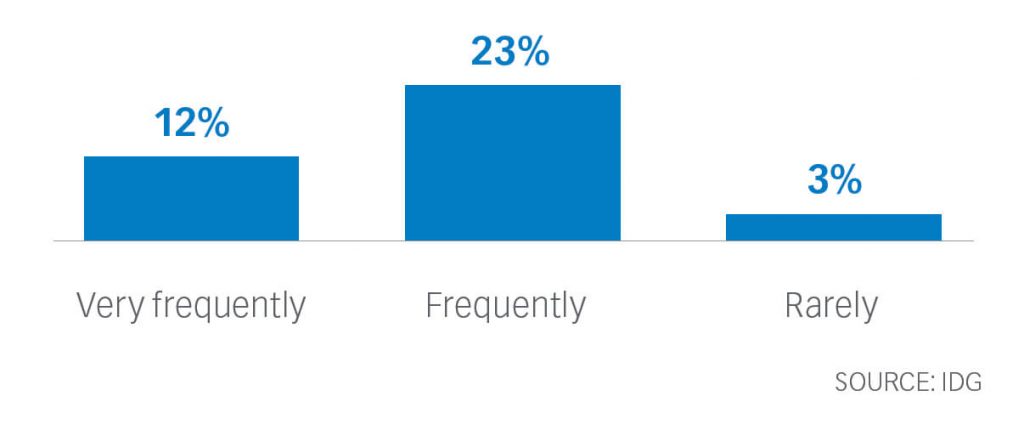

Many organizations lack sufficient IT staff to create the digital backbone necessary for supply chain integration: 35% of the survey respondents said that the number of trained workers falls short of their needs on such undertakings (12% said very frequently, 23% frequently). Such a gap is likely to prevent or at least discourage projects from getting started, due to the expense of hiring additional workers or training current staff. (See Fig. 3)

A further problem is the quality of data from external partners. Only about two-thirds of external partner data is considered accurate. The data comes from many sources, including inventory, supply chain, products, sales, customers, employees, logistics, and contracts. Regardless of the source, the average percentage considered accurate in each category ranges from 63% to 67%.

When the need for high-quality data to carry out supply chain operations competently is considered, the rate of data accuracy reflected in the survey is cause for concern. A two-in-three chance of accuracy is a clear indication that there is considerable room for improvement. Organizations would be well advised to implement techniques such as normalization to improve data quality.

Integration tools and services

Given the importance of supply chain integration and the widespread practice of carrying out electronic transactions, it’s not surprising that more than nine in 10 respondents use an integration tool of some kind. The average number of tools in use at each respondent’s company is 2.6.

More than nine in 10 respondents use some form of data integration tool.

Notably, 43% use a business-to-business (B2B) service provider or value-added network (VAN) to cut costs by securely and reliably exchanging all types of trading documents with partners worldwide. Such B2B cloud networks typically include tools for electronic data interchange (EDI) and B2B integration.

The survey highlights differences between SMB respondents (with fewer than 5,000 employees) and enterprise organizations (with more than 5,000 employees). The greatest difference in the use of integration tools is found in two categories:

B2B services provider/VAN: 38% of SMBs, 48% of enterprises. Enterprises are likely to be attracted to B2B services providers/VANs, because they support EDI and offer customization capabilities.

Enterprise service bus (ESB): 46% of SMBs, 35% of enterprises. SMBs are likely to implement and operate ESBs as a legacy method of integration, leveraging their internal knowledge or service provider relationship. ESBs are capable of delivering short time-to-value, but they do not scale well in cloud environments and are more suitable for on-premises environments.

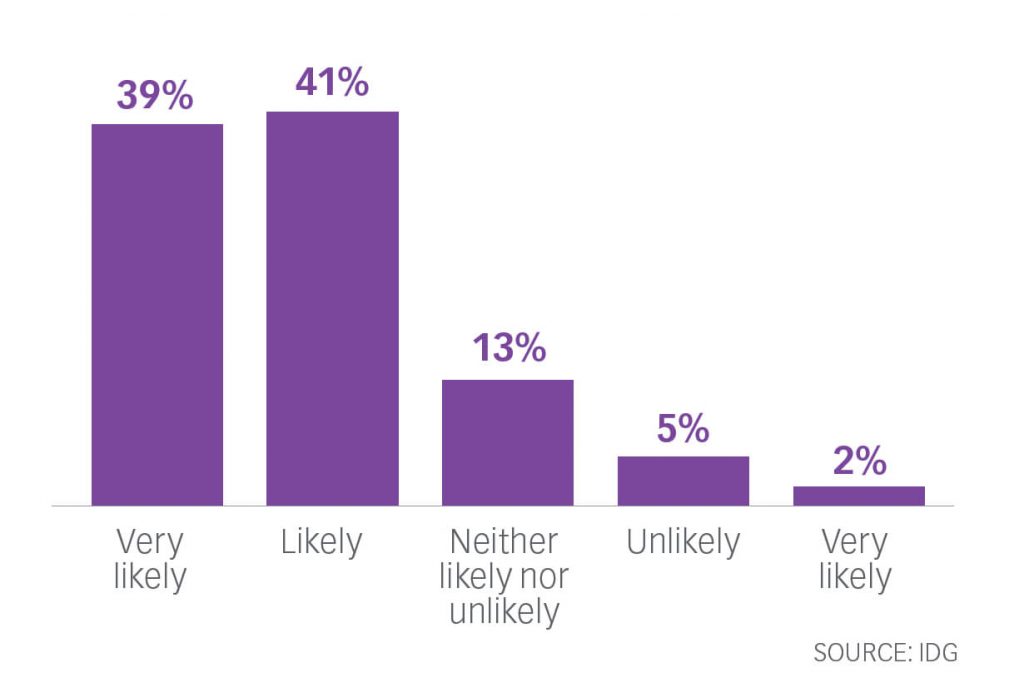

Besides using tools, a strong majority (80%) of the respondents are likely to call on third-party partners to support their complex data integration projects (39% say they are very likely to do so; 41% say they are likely to do so). (See Fig.4)

One reason is probably the lack of staff skilled in the use of integration technologies. The willingness of respondents to work with a third party indicates that they see that option as preferable to the time and expense of hiring and training staff to carry out integration projects. (See Fig.5)

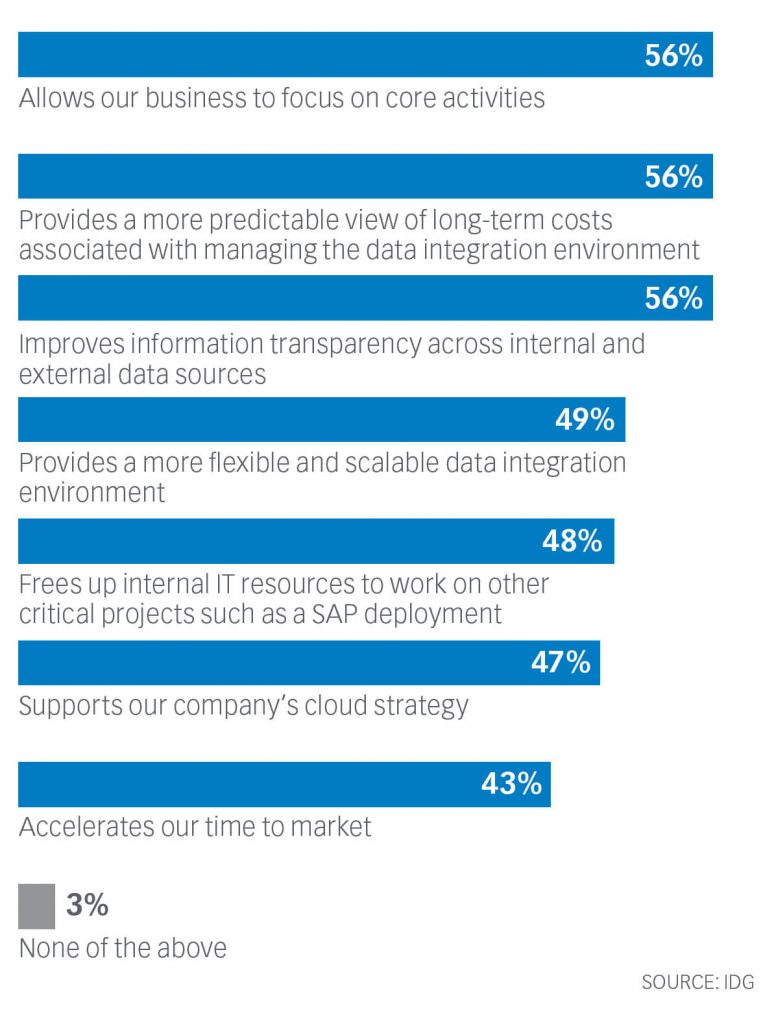

These factors are reflected in the benefits respondents see in using a third-party integration partner. The benefits of using a third-party partner to help with data integration are wide-ranging (see chart). However, the ability to focus on core activities (56%) and the ability to free up internal IT resources to work on other critical projects such as SAP deployment (48%) are two factors that tie directly to staffing and training.

Conclusion

Companies recognize the importance of supply chain integration, and most have embarked on the journey to implement a digital supply chain. Faced with obstacles such as staffing and data quality issues, organizations are implementing a variety of supply chain integration tools. Significantly, they are likely to call on third-party integrators to carry out the effort.

Given the benefits of a digitized, integrated supply chain, it is incumbent on companies to continue on their integration journey, eliminating paper-based transactions wherever they remain. A fully integrated electronic supply chain enables a company to leverage the data flowing across the internal and external enterprise. Data can be analyzed to spot areas that are not yet optimized, efficiency can be evaluated, and data quality can be understood and improved. In short, an integrated electronic supply chain acts as a digital nervous system, giving a company greater agility, greater responsiveness to partners as well as customers, and greater competitiveness.

The OpenText solution

The receptiveness of survey respondents to a third-party integrator indicates that they are ready for OpenText Trading Grid. OpenText is the leading cloud integration service provider addressing the core problems of data integration and data quality. OpenText Trading Grid is the industry’s only unified integration platform delivered as a technology-enabled managed service, where OpenText experts take on the complex integration and data normalization work for you, enabling standardized, uniform processes and best practices across your enterprise.

A fully integrated electronic supply chain enables a company to leverage the data flowing across the internal and external enterprise.

A fully integrated supply chain with normalized data enables business leaders to gain insights into suppliers, inventory, and operations rapidly. Those insights can, in turn, guide actions that increase efficiency and responsiveness to partners and customers. OpenText Trading Grid helps organizations orchestrate the most-complex integration processes with a unified and simplified approach that enables seamless information flows. Companies move data across growing, multienterprise ecosystems that connect trading partners, applications, and devices, whether in the cloud, on-premises, or in hybrid environments. Using this advanced platform, companies connect once and reach anything.

In addition, OpenText operates the world’s largest business network, transforming integration among more than 800,000 businesses worldwide.

For more information visit us at https://businessnetwork.opentext.com/.